Apples to Apples: Developing a Framework for Environmental Impact Comparison for Lithium Chemical Products

Robert Pell, President, Minviro, London, UK

Laurens Tijsseling, Sustainability Manager, Minviro, London, UK

Alex Grant, Principal, Jade Cove Partners, San Francisco, USA

David Deak, President, Marbex, Palo Alto, USA

April 2020

The PDF of this article is available here and its associated LinkedIn post is available here.

Lithium chemicals are essential for our transition to a low-carbon economy. However, like many other raw materials needed for the energy transition, the frameworks that quantify the environmental impacts of their production are not well developed. Since we published the first life cycle assessment (LCA) of the lithium battery chemical supply chain in January 2020, (1) we realized that current environmental impact models are underdeveloped to such an extent that we have had to build our own LCAs on the chemical products that go into manufacturing lithium chemicals. Most database values and publications are not representative of what is actually happening in industry.

The ability to quantify the environmental impacts of lithium chemical production, at any stage of development, is more important than ever. There is greater public awareness of environmental impacts of lithium extraction, as well as advancing international regulations and standards. Purchasers and downstream users of lithium chemicals demand more information about the environmental credentials of the chemicals they buy. Lithium producers are attempting to differentiate themselves from peers by claiming low environmental impact and high standards of corporate responsibility. It is estimated that the CO2 intensity of manufacturing an electric vehicle is around 2.5x higher than an ICE vehicle, mostly because of battery manufacturing. Many groups are working on changing this. (2) Recently, lithium buyers have decided to go to Chile themselves to gather their own data to evaluate ESG (Environmental, Social and Governance) impacts of Salar de Atacama lithium chemical production on freshwater resources and local communities. (3)

Despite the obvious motivation to model environmental impacts, decades of greenwashing and fuzzy sustainability metrics have fueled consumer skepticism and scrutiny in relation to environmental credentials. In this article, we propose a roadmap for how we can solve some of these challenges for lithium chemicals in particular. We articulate how LCA can be a powerful tool to mitigate environmental impacts when properly used. This approach is the foundation for responsible sourcing strategies, and for the production of premier, low-impact lithium chemical products.

Standards and Codes

The number of sustainability codes and metrics have proliferated over the last few years. They include a range of approaches, all with slightly different data requirements and methodologies, providing a range of results for different stakeholders. The codes are often regionally specific. Many of these different approaches feed the “environmental” in “ESG” (Environmental, Social and Governance) scoring matrices. These methods can include voluntary schemes such as the Carbon Trust Standards, the Greenhouse Gas Protocol, the Task Force on Climate-related Financial Disclosures (TCFD), the Sustainability Accounting Standards Board (SASB), and the Global Reporting Initiative.

There are other schemes such as the Extractive Industries Transparency Initiative (EITI), The EU Emissions Trading Scheme (EU ETS), and international equivalents. There are also frameworks and policies from the International Council on Mining & Metals and the Initiative for Responsible Mining Assurance. This list is not exhaustive, but highlights the dizzying number of standards that are covering similar ground. For example, many schemes are focused explicitly on greenhouse gas emissions, in contrast to a fully ISO-compliant LCA which should consider a range of impacts.

This makes the approaches mentioned above a subset of LCA. Reducing greenhouse gas (GHG) emissions is a global priority and a challenge which requires great focus. Yet, by assessing GHG impact alone we are missing a fundamental point. LCA is a process which incorporates systems thinking, and exploring the impacts associated with trade-offs between different impact categories. By narrowing our focus exclusively to reducing GHG emissions, we may miss unwanted increases in other impact categories. For example, if we used biodiesel as an energy source near a mine site, carbon intensity may fall at the expense of local biodiversity. That is, a GHG-only study would miss the trade-off and an unwise investment decision might be made. The same is true for lithium production processes from different types of natural resources.

Below is an overview of common impact categories (from the ReCiPe framework) in LCA and how they are related. (4)

Corporate vs. Product-Oriented Assessments

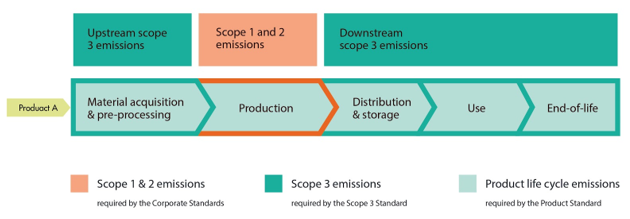

There is often confusion between corporate level sustainability assessments (organizational LCA) and product-oriented studies. Corporate assessments are aimed at supporting impact reduction at a corporate level, whether full organizational LCAs or following the Greenhouse Gas Protocol’s Scope 1, 2 or 3 GHG emission assessments. The system boundary for these types of studies include corporate activities (such as executive travel) and are not specific to a company’s individual products or services.

Product-oriented LCAs focus on identifying the life cycle emissions and impacts associated with the production (cradle-to-gate) and use (cradle-to-grave) of a specific product. This includes embodied emissions from the raw materials supplied by vendors, manufacturing and equipment, transport, storage, use, and disposal. This is an important distinction to make when modeling the environmental impact of lithium chemical production. For example, lithium consumers may want to focus on product-oriented LCAs, whereas investors/shareholders may rely on corporate-level LCAs for decision making. Further, chemical production can be the driver of impact vis-à-vis corporate activity, and be used as an engineering tool to improve environmental and operating performance, as indicated in a Minviro LCA case study of rare earth mineral production. (5) Below is an overview of the different scopes of emissions for product-oriented LCAs. (6)

Corporate assessments can also include these embodied impacts but more commonly only assess Scope 1 and 2 emissions. LCAs for lithium chemical products should be modeled as product-oriented LCA with upstream Scope 3 emissions because this allows downstream assessments to incorporate the lithium chemical products ‘module’ within larger studies, such as in battery or electric vehicle LCAs.

Needed: A Product Rule for Battery Quality Lithium Chemicals

To ensure an “apples to apples” comparison across a single product category, such as battery-quality lithium carbonate or lithium hydroxide monohydrate production, the industry needs clarity and consistency with implementing LCAs. Currently, lithium chemical producers and project developers can arbitrarily adjust the boundary for what is included in their environmental performance calculations. In addition, co-product impacts can be treated in a range of potentially misleading ways, and subjectively selected proxy data may skew accuracy of LCAs. To remedy this and to ensure that studies are consistent and comparable, a product rule needs to be developed by an independent LCA-focused professional organization.

A product rule is a document created by a group of stakeholders with an interest in a particular product or product category, with the goal of building consensus on the specifications needed to enable comparisons or declarations about the product. An example of the creation of a product rule developed according to EU guidance (PEFCR) for steel, copper and aluminum can be found online. (7) There is a process in place to develop product rules and this is presented in the ISO 14025:2006(E) Environmental labels and declarations - Type III environmental declarations - Principles and procedures - Annex A. Once this is complete, the product rule should enable different practitioners to generate consistent results when assessing products of the same product category.

It is important to have this product rule for lithium and other battery metals. It enables visibility into tangible metrics that companies and shareholders can leverage, as a means for improving financial, environmental, and reputational performance. It also allows better policy modeling for future development scenarios. By following a clear product rule, these models can become a module for studies further down the supply chain. It is also critical that all models follow the same product rule, to maximize the transparency of the environmental modeling process and prevent deception. Further, it is critical that environmental impact models are ISO-compliant. This is the only way to ensure we can make “apples to apples” assessments. Lithium industry stakeholders now have an unprecedented opportunity to lead on this front, removing ambiguities on environmental performance, by using ISO-compliant LCAs for which Minviro is setting the standard.

A product rule for lithium chemical LCA will be the first to connect lithium industry specifics with LCA best practice. For example, lithium is one of only a handful of chemical products that is produced by evaporation of salt brines from complex hydrogeological networks such as the Salar de Atacama. The lithium LCA product rule will present a framework that clearly separates water impacts of the water in the brines, fresh water extracted for process, and the potential impacts of brine extraction on less salty aquifers that are connected via hydrogeological networks. This can reduce substantial confusion on this topic, that generalist LCA developers are not equipped to tackle.

There is significant demand from various stakeholders in the lithium sector to have a fair and representative comparison for the environmental performance of lithium products from different sources. In order to ensure this comparison is fair and consistent, a product rule is needed. Minviro will be developing the product rule draft for lithium products over the coming months. We encourage input from across the industry. If you are a lithium industry stakeholder such as a purchaser with an in-house LCA team, a lithium producer looking to communicate your environmental performance, or an LCA methodology professional, please feel free to reach out at info@minviro.com.

References

(1) Alex Grant, Robert Pell, and David Deak. The CO2 Impact of the 2020s Battery Quality Lithium Hydroxide Supply Chain. URL.

(2) VW ID Insights Sustainable E-Mobility Presentation.

(3) Volkswagen. Fact-finding expedition to the lithium desert of Chile. URL.

(4) UK National Institute for Public Health and the Environment. LCIA: The ReCiPe model. URL.

(5) Robert Pell, Frances Wall, Xiaoyu Yan, Jinhui Li, and Xianlai Zeng, Mineral processing simulation based-environmental life cycle assessment for rare earth project development: A case study on the Songwe Hill project. URL.

(6) Greenhouse Gas Protocol, 2018. Product Life Cycle Accounting and Reporting Standard. URL.

(7) PEFCR Guidance ver. 6.3, 2018. Product Environmental Footprint Pilot Guidance, Guidance for the implementation of the EU Product Environmental Footprint (PEF) during the Environmental Footprint (EF) pilot phase. URL.