Much Ado About Unconfined Aquifers?

Alex Grant, Principal, Jade Cove Partners, San Francisco, USA

Chris Doornbos, CEO, E3 Metals, Calgary, Canada

November 2020

The PDF of this article is available here and its associated LinkedIn post is available here.

Lithium extraction from brines in South America has received some bad press over the last couple years due to its “water consumption”. Beyond concerns about true freshwater consumption which may reduce availability of water for human use, the problems in Chile in particular are more complex. The main issue locally in Chile is the possibility that extraction of very high salt content “brine” waters (~300g/L of salt) from shallow under the surface of the desert may cause other less salty waters (e.g. < 2 g/L of salt) which sit on top of the brines to be disrupted if the levels of the brines drop. This is a particular concern at the Salar de Atacama, where a major producer recently announced they plan to reduce brine extraction by half by 2030. (1) The hydrological risks of extracting brine from a subsurface system to produce lithium chemicals are unique to each setting and the types of aquifers that these systems are composed of. There are two fundamentally different types of aquifers which may contain waters such as those that lithium can be produced from: confined and unconfined aquifers.

An unconfined aquifer usually contains water hosted in the ground near or at the surface. Water at the top of the aquifer is at atmospheric pressure and its temperature is close to the average temperature of the air above it. When water is produced from these aquifers and not returned, the elevation of water decreases unless water is returned to the aquifer (which could be the brine with the lithium removed, or another inflow from another aquifer). As unconfined aquifers are typically close to the Earth's surface, they can be connected to surface water. Salar brines in South America are often found in unconfined aquifers.

A confined aquifer contains brine hosted in the ground at a greater depth which makes it less connected to the surface and atmosphere. Pressure in these aquifers is greater than atmospheric and typically warmed by the Earth’s core to higher temperatures. When water is produced from these aquifers and not returned, the pressure of the water decreases. Oilfield and geothermal reservoir waters are typically found in confined aquifers. (2) If too much water is removed from a confined aquifer, the pressure of the aquifer will drop which will mean more energy is required to extract the water from the well. Therefore, to enable long term production of water for mineral extraction or energy recovery from confined aquifers, the pressure of the aquifer must be maintained, and in many cases, water may have to be put back into the aquifer.

It may be possible to “sustainably” extract and evaporate water from brines in unconfined aquifers if there are no significant ecosystems or important low salt content hydrological systems in the same basin as the brine extraction, and importantly with the right dry climate. (3) However, these hydrological risks are mostly absent in the case of deep confined aquifer brines. This means the impact of extraction and re-injection of brines in confined aquifers is less likely to impact water availability for humans and animals which do not live deep underground.

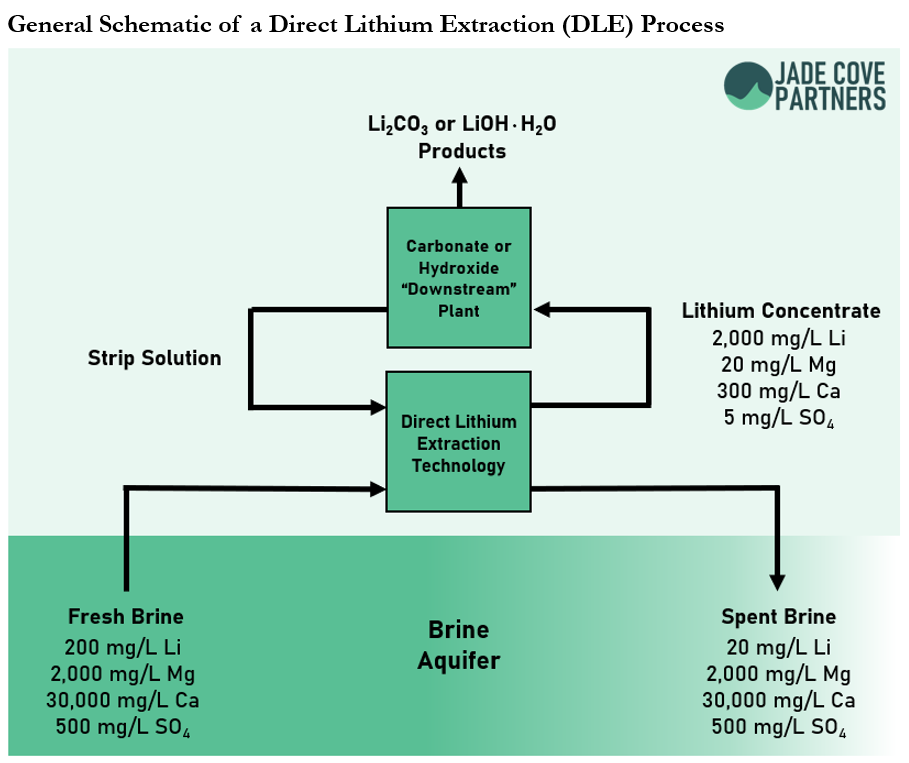

To produce brine from a confined aquifer over a long period of time, the pressure must be maintained. In some cases, this can be achieved if the reservoir is laterally continuous across a large area or the hydraulic properties are favorable enough to support the production of brine. In most cases, however, the brine must be put back into the aquifer after the lithium has been removed. If not, the aquifer will depressurize, and at some point, it will not be possible to economically produce more brine from the aquifer. This means that if a mineral like lithium is extracted from the brine, the lithium must be directly removed without evaporating the water from the brine. This is where extraction processes such as direct lithium extraction (DLE) can be applied. The use of DLE for lithium production from confined aquifer brines is a requisite for these brines also because many new confined aquifer brines contain higher impurity concentrations than unconfined aquifer brines, such as those in South America. This means that evaporative/chemical processes to produce lithium from these brines are not economic. A schematic of the operational use of DLE is shown to the right. As of Q4 2020, Jade Cove is following progress of over 60 DLE technology solutions in development or operation globally.

There are a number of confined aquifer lithium projects in development around the world, with a number of compelling ones in North America such as in California, Arkansas, and Alberta. Most unconfined aquifer brine lithium resources are found in Chile, Argentina, Bolivia, and China. There are two reasons for this geographical separation between projects developing these two types of brines. First, confined aquifer brines are harder to find and understand because they are deep, but have been discovered on the hunt for other resources. Most of the big confined aquifer brinefields were first discovered and developed for uses other than lithium (e.g. oil & gas, geothermal energy, bromine). Second, more advanced DLE technologies are required to produce lithium from these brines and these technologies are less widely understood than evaporation processes. DLE technologies have mostly been developed in North American jurisdictions precisely because of the desire to produce lithium from higher impurity, lower lithium concentration brines in confined aquifers. In fact, DLE was first invented by Dow Chemical in order to produce lithium from Southern US oilfield brines.

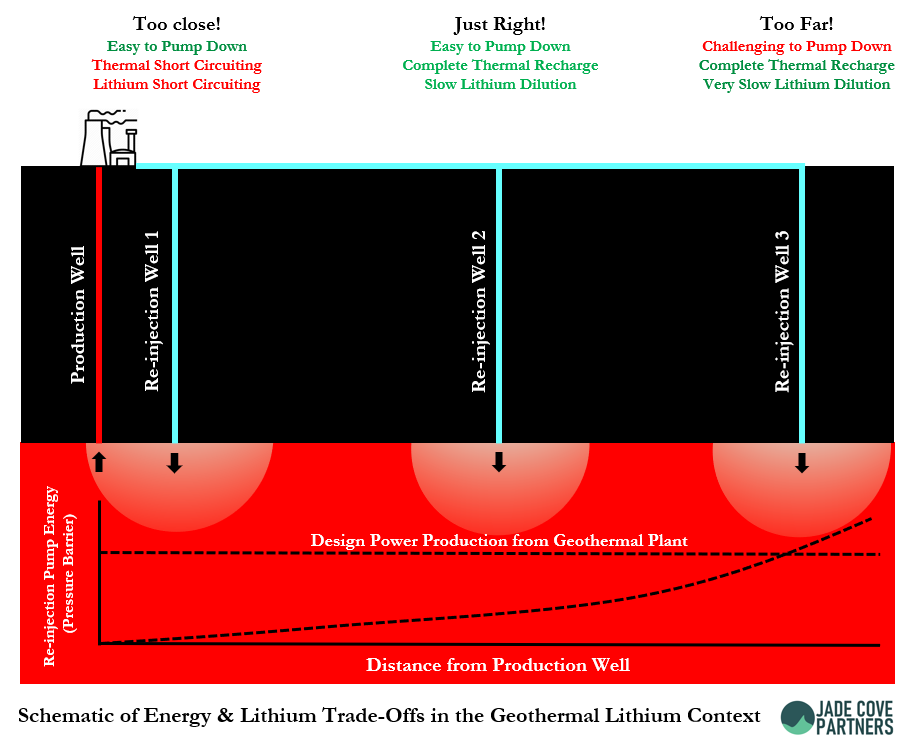

An interesting new challenge arises for projects looking to produce lithium from confined aquifers: if the brine must be re-injected in order to maintain aquifer pressure (and it needs to go somewhere anyways if a DLE technology is used), then how does one prevent the fresh brine (with lithium) from not mixing with the spent brine (without lithium)? In a production scenario, there is a possibility of pumping up the spent brine in the production well, short circuiting the system. If this “short circuiting” occurs at a large lithium project, it would require additional mitigation costs such as drilling new wells further away. This means it is critical to employ strategies to prevent brine short-circuiting. Further, what if multiple operations are built in the same brinefield: could one operation produce the spent brine of another operation, shutting down lithium production for the unlucky operation? This could become a problem in all brinefield jurisdictions mentioned above. Although the confined aquifers in each case are very large, lithium projects typically operate for 20+ years, and problems could arise in the brinefield long after an operation has started producing lithium. Existing rules of thumb and regulations developed for historical confined aquifer brinefield development are crucial for preventing these types of issues. Here is a schematic of how “thermal short circuiting” is avoided in the geothermal energy context, in which case energy is extracted from a confined aquifer brine instead of a material.

The history of air travel regulation in the US provides a helpful analogy. It used to be thought that the sky was too big for two airplanes to ever collide. Until 1956, most of the air across the U.S. was “uncontrolled”, meaning pilots kept their distance from each other manually. In that year, two planes improbably collided over the Grand Canyon, killing 128 people. This led to the founding of the Federal Aviation Administration in an attempt to prevent similar accidents from happening again. In this case, rules and regulations were developed to mitigate risks of above ground operations. The hydrological risks of producing from and reinjecting into a shared confined aquifer below ground also benefit from rules, regulations, and experience.

In this paper, we overview the history and state of play of brine extraction from confined aquifers across North America which are now being targeted for lithium chemical production to feed the EV battery revolution. Across the continent, we find that historic brine production from confined aquifers is a key factor for streamlining the development of these brines for lithium production, and helping to ensure that these projects will not face “short circuiting” brine dilution issues in the future.

California

The Salton Sea Trough is the surface expression of a deep, sediment-filled rift valley created by the San Andreas Fault at the Northern edge of the Gulf of Mexico (where the Pacific and North American tectonic plates meet, and where California is slowly peeling off from the rest of the U.S.). Its namesake is a saline lake just South of Palm Springs which did not exist when California was settled, but was formed when a pipe carrying water from the Colorado River burst in 1905 and flooded into the valley. It was at one point a tourist destination and fishery, but with no surface outflow, the lake accumulated salts and now has too high of a TDS to support significant life. It also has a terrible smell of death. The Salton Sea proper is not a lithium resource though. It is the very hot, high TDS saline brine-filled confined aquifer thousands of feet deep that contains large lithium, not the drying lake. The aquifers containing this brine are extremely hot and pressurized because of the shallow tectonic deformations associated with the San Andreas Fault. There are small surface expressions of the high energy fluid in the Southern shore of the Salton Sea, which prompted the first geothermal energy exploration in the 1920s.

Hot brine and steam, produced when the hot brine was depressurized by bringing it to the surface, were discovered early on. It was found that a large quantity of CO2 gas also came out of solution from the hot brine. This became the first brine-derived resource at the Salton Sea, where carbon dioxide was produced and cooled to make dry ice from the 1930s to 1950s. Other wells were drilled to explored for oil and gas, but in most cases it was mostly hot brine which was produced instead. This drilling did have a side product of delineating large quantities of geological data. The high salinity and content of the dissolved metals and silica caused scaling issues when handling the brine, which were only solved using more advanced geothermal energy extraction technologies in the 1980s. There has also been historic calcium chloride and other salt production from the brine. (4)

There are now more than 10 geothermal energy plants operating in the Salton Sea area, producing half a gigawatt of relatively low CO2 intense power. Because of the prevalence of solar power and natural gas in the Southwestern U.S. though, there is significant pressure on the price of energy, meaning that power purchase agreements for geothermal power are mostly valued at less than 10 cents/kWh. This makes it hard to finance pure-play geothermal energy projects in the Salton Sea Geothermal Field. It has caused developers to focus on development of processes to co-produce lithium and other chemicals from the brine in combination with energy production to improve project economics of building new geothermal energy capacity. In the early 2000s, Berkshire Hathaway spent millions of dollars on a zinc extraction operation which went bankrupt. Three developers are currently advancing geothermal lithium schemes in the Salton Sea, including Berkshire Hathaway, EnergySource, and Controlled Thermal Resources, all contemplating different approaches to DLE and lithium process. (5)

Arkansas

Oil production began from the Smackover Formation in Southern Arkansas in the 1920s, and at one point had the highest oil production in the U.S. The Smackover is a limestone-dominated geological formation between 6,000-10,000 feet deep that stretches from Texas into the Gulf of Mexico. When oil was produced from the Smackover, brine came along with it. That brine was initially disposed of, but later on became a resource for development itself. Bromine recovery from the brine began in Arkansas in 1957, and now Arkansas is one of the most important bromine producing regions in the world. (6)

In Arkansas, land ownership and right to minerals under that land do not necessarily have to go hand in hand. In the case where a land owner does not develop a mineral asset under their property, including bromine or lithium from brine, they can negotiate a mineral lease agreement with a developer who does want to produce a chemical. The structure for mineral leases was originally set up by the Arkansas Oil & Gas Commission (AOGC) to manage the way minerals were leased for the bromine industry. Since the agreements govern the extraction and production of bromine (and alkaline earth elements in some localized cases), additional compensation of mineral lease holders for lithium and other products can be completed as “in lieu” royalty payments in the case of companies which want to develop a secondary value stream. For more than six decades, brine has been continuously produced from the Smackover, bromine extracted, and brine re-injected with no brine short-circuiting/dilution issues, at least in part because the resource is so hydrogeologically consistent and extensive. This history of brine extraction in the Smackover is a positive sign that lithium extraction from the same resource could be successful depending on the DLE technology approach.

There are a number of lithium projects in development in the Smackover. Standard Lithium partnered with Lanxess, a bromine producer, to demonstrate a functional ion sieve DLE technology at the site of a current brine operation in Southern Arkansas. In Q4 2020, they are currently operating a demonstration plant to prove out the technology at pre-commercial scale. (7) Further, Albemarle has patented DLE processing flowsheets in recent years, and received a small amount of funding in 2020 from the Department of Energy to continue advancing a process that could be used to produce lithium from their Smackover brine operations as well. (8)

Alberta

Similar to Arkansas, production of brines from deep aquifers in Alberta, Canada was started by the oil and gas industry. In Alberta, large lithium resources have been identified in the Leduc and Nisku aquifers, which were discovered by Exxon in 1947. This discovery led to an oil rush in the province, which now hosts the third largest oil reserves in the world. (9) The Leduc Aquifer is 1,800-3,000m deep (5,400-9,000 feet) and generally around 200-250m (500-750 feet) thick. The high porosity and permeability of the dolomitized Leduc aquifer allows for large brine production volumes. The Leduc has only minor oil production today and produces 95-98% water from once oil rich areas. However, the majority of the aquifer never hosted economic concentrations of oil, but was still rich in brine. So mineralized brine is a central feature, not a bug, of these aquifers in Alberta.

Using vast historical data from oil and gas exploration, the geological risks of developing a new brine project in Alberta can be minimized. This deep understanding of the brinefield combined with the provincial government’s desire to diversify its economy provides a perfect opportunity for the growth of the lithium industry in a historically sophisticated industrial jurisdiction. In Alberta, the minerals rights that include lithium are acquired separate from oil rights. In areas, there is both government-held mineral rights that can be leased and freehold-held mineral rights that can be purchased or leased. Royalties in Alberta are well established for minerals for government held land and negotiated individually with freehold landowners, which are historically and generally the same as government royalties. Oil production in the province in governed by the Alberta Energy Regulator, who provides permits for drilling wells, the installation of pipelines and the development of processing facilities. In the case of well licenses, they generally come in pairs consisting of both production wells and injection wells, as there is no allowable surface disposal for saline ground water, which is governed differently than freshwater under the Alberta Water Act. Facilities in Alberta that still produce oil from the Leduc are designed to handle large volumes of brine and therefore makes the production of lithium in the province operationally nearly identical to oil production. Similar to the Smackover, the production of fluids in Alberta that already exist make the application of DLE to mineralized Leduc brines containing lithium an easy and minor addition to current operations.

There are several lithium projects in various stages of development in Alberta. E3 Metals owns a large portion of the Leduc and Nisku Aquifers in central Alberta. They have partnered with Livent to develop an ion-exchange DLE process which they plan to pilot on-site in 2021. In 2020, they published information on the development of their aquifer management plan to mitigate risks around brine short-circuiting leveraging the extremely large size of the aquifer, a solid understanding of the aquifer’s geological characteristics, and a systematic approach to managing the long-term behavior of the brine and its mixing patterns.

Unconfined Aquifers: Much Ado?

Producing lithium from Northern Hemisphere confined aquifer brines may be one of the lowest ecological risk ways to manufacture lithium chemicals from natural brine resources since unconfined aquifers are typically separated from surface freshwater which life depends on. The heat in these brines may also be useful for producing energy, driving chemical reactions, or facilitating economic DLE.

There are a number of compelling confined aquifer brines based in stable North American jurisdictions which investors are comfortable with such as California, Arkansas, and Alberta. In these places, decades of brine production for other products is being leveraged to streamline and accelerate lithium chemical extraction projects. This is a major advantage for these brine projects, and investors and customers should seek to understand these regions’ historic brine industries to evaluate the prospects of future lithium production from these brines.

Confined aquifer brine projects are likely to be successful if they have access to large quantities of brine, a high level of understanding of their geology imported from other industries, and an aquifer management plan that leverages these things in order to ensure brine short-circuiting is minimized or prevented. Each confined aquifer is unique. Those being developed in California, Arkansas, Alberta, and elsewhere have their own unique geological parameters. It is important to always contemplate the specific features of these resources when evaluating them, and to not rely on generalities.

Acknowledgements

Thank you to Steve Shikaze of Matrix Solutions, Andy Robinson of Standard Lithium, Darrell Gallup of Thermochem, Gordon Macmillan of Fluid Domains, and Gene Morgan of Zelandez for their thoughtful reviews of this article.

References

(1) Mining.com, 2020. SQM to cut water, brine use by 50% over ten years. URL.

(2) USGS, 2020. What is the difference between a confined and an unconfined (water-table) aquifer? URL.

(3) Ferguson, Cuthbert, Befus, Gleeson, and McIntosh. The groundwater age-sustainability myth.

(4) Lawrence Livermore Laboratory. Geothermal Development of the Salton Trough, California and Mexico.

(5) New Energy Nexus. Building Lithium Valley. URL.

(6) Arkansas Geological Survey. Bromine (Brine). URL.

(7) Mining Magazine. Standard Lithium Ships First Product from Demonstration Plant. URL.

(8) Albemarle. Albemarle Selected by U.S. Department of Energy for Lithium Research Projects. URL.

(9) NS Energy. Top ten countries with the world’s largest oil reserves, from Venezuela to Iraq. URL.